DRYING KILNS

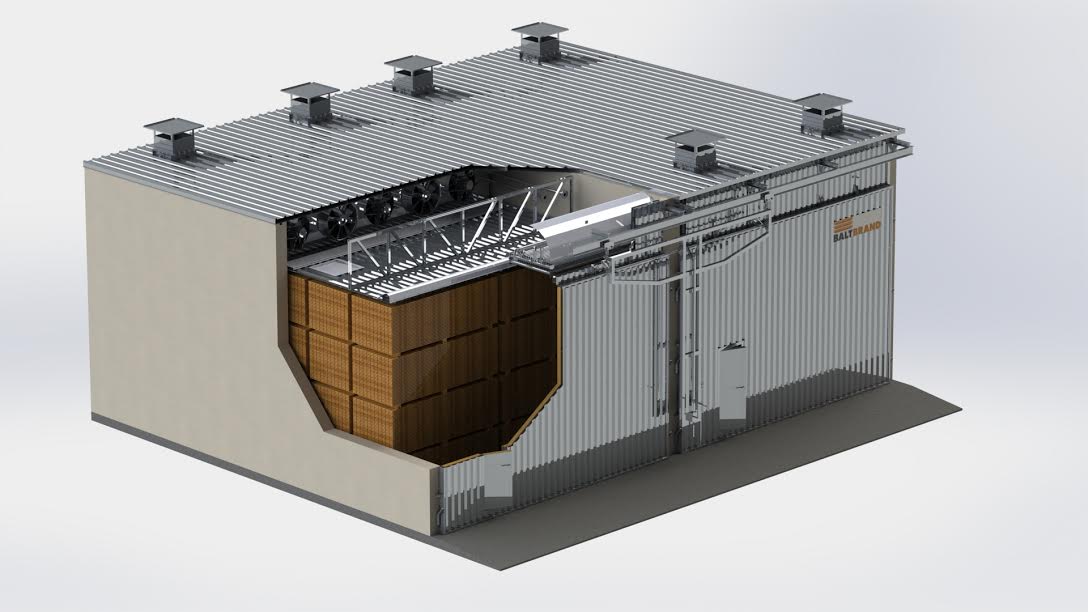

Traditional drying kiln TTK (for HT-pallets)

The most common type of dryer is a convection drying kiln with front loading. Its casing and cladding is made of aluminum. Wall thickness up to 200 mm, truck loading.

Capacity: 40-350м3

Final Humidity: 8-10% / 16-18%

Insulation: stone wool

Heat carrier: hot water, steam, thermal oil.

Humidification: low pressure or high pressure.

Snow load: 240 kg / m2

Winds from the NW at 130 km / h

The dryer is equipped with a control system that allows remote control of the processes.

* HT (heat treatment) mode - Each of our drying chambers can also be equipped with HT mode, which is used to handle pallets in accordance with ISPM 15 standards.

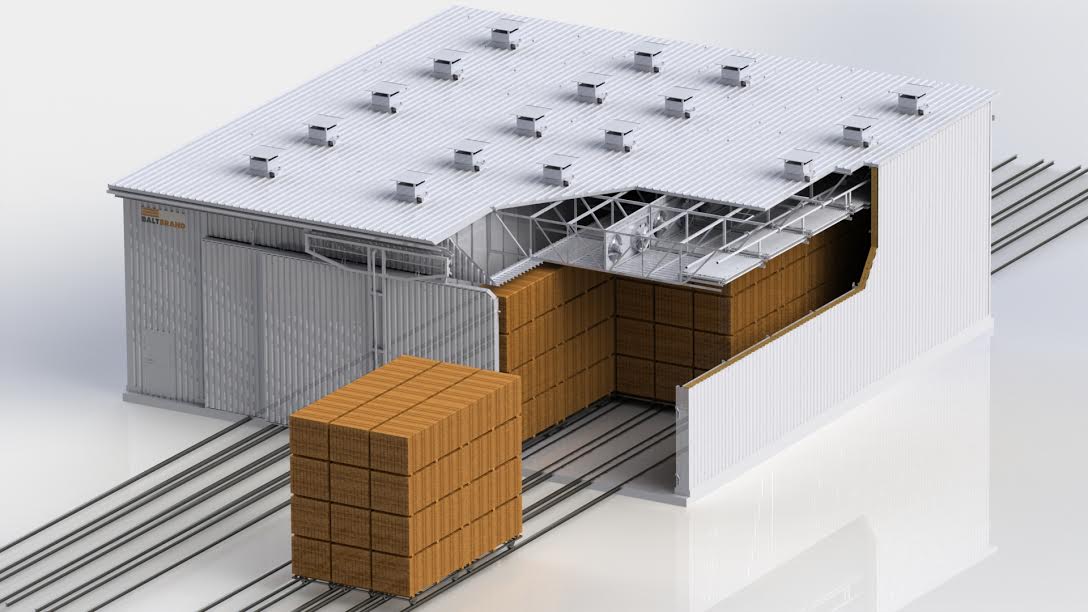

TTK -T tunnel drying chamber

Tunnel-type drying chambers are convection-type chambers that can achieve all the same characteristics but differ in the way they are charged. In such drying chambers, wood is loaded onto trolleys and moved along rails. For this reason, tunnel-type drying chambers are usually chosen for fast loading and unloading, as well as quick drying. - a short cycle that dries the wood to moisture in transport, which is more often suited to building materials. However, such dryers can also easily reach the traditional 8-10% humidity level, so they can also be used in plants where this type of loading is more appropriate to the processing process.

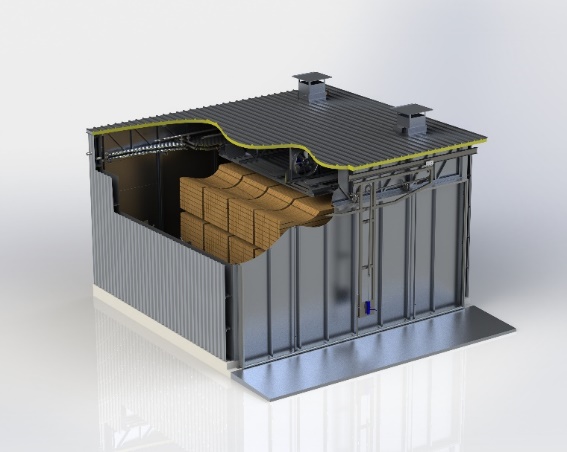

Built-in drying chamber - TTK-B

Although the drying chamber frame is traditionally made of aluminum, we also offer the client, in cooperation with our specialists, the possibility to construct this frame from concrete or brick. It is also possible to install a drying chamber in existing buildings.

Steam chambers TTK-S

Steam chambers are used to change the wood's parameters - color and elasticity. They can be designed as convection drying chambers with further evaporation process.